Agitated Thin Film Dryer

An Agitated Thin Film Dryer (ATFD) is a specialized drying system designed to handle challenging applications involving the evaporation and drying of high-viscosity, heat-sensitive, or thermally degradable materials. It works by spreading a thin layer of the feed material over a heated surface with the help of an agitator, allowing rapid evaporation and efficient drying.

Paddle Dryer

A Paddle Dryer is a highly efficient, indirect heat transfer system used for drying and cooling applications. It consists of a horizontal cylindrical vessel equipped with rotating paddle-shaped agitators. The design ensures uniform heat transfer and effective mixing of materials, making it ideal for handling slurries, pastes, powders, and granular materials.

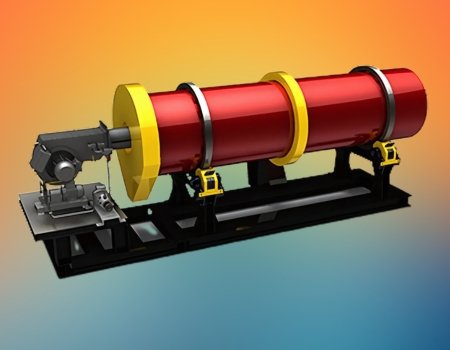

Rotary Tube Bundle Dryer

Continuous Fluid Bed Dryer & Cooler

A Continuous Fluid Bed Dryer & Cooler is an advanced drying and cooling system designed for handling granular or powdered materials efficiently. It operates by suspending the material in a stream of hot or cool air, creating a “fluidized” state that allows uniform heat transfer, rapid drying, and effective cooling in a single, continuous process.

Rotary Dryer & Cooler

Flash Dryer & Cooler

A Flash Dryer & Cooler is a high-speed, efficient system designed to dry and cool materials in a matter of seconds. It works by suspending fine particles in a hot or cool air stream, leveraging the principle of fluidization to ensure rapid heat and mass transfer. This system is ideal for processing heat-sensitive, non-sticky, and free-flowing materials.

Spray Dryer & Cooler

A Spray Dryer & Cooler is a specialized system designed for the rapid drying and cooling of liquid or slurry feed into fine powder or granules. This process involves atomizing the feed into small droplets, which are then exposed to a hot air stream for drying, followed by a cooling stage to stabilize the product. This equipment is ideal for industries requiring precise control over product characteristics like particle size, moisture content, and bulk density.

Agitated Cage Mil Flash Dryer

The Agitated Cage Mill Flash Dryer is a high-efficiency drying system designed for processing heat-sensitive, fine, and sticky materials. It integrates drying, de-agglomeration, and size reduction in a single operation. This innovative design uses a combination of mechanical agitation and hot air to produce uniform and rapid drying, making it ideal for handling challenging materials.